Piezoconcept

Piezoconcept is a leading provider of nanopositioners for applications such as superresolution microscopy, optical trapping, and AFM. Products feature low noise electronics and a flexible design stage for a subnanometric (or subnanoradian) noise floor. The company was established in 2013 and is based in Lyon, France.

On-Trak is Piezoconcept’s distribution partner for North America.

Application

The company’s nanopositioning equipment and positioning stages meet a wide range of meet a wide range of microscopy applications including:

-

Super Resolution Microscopy

-

Adaptive Optics

-

Optical Trapping

-

High-speed Confocal Imaging

-

Scanning Probe Microscopy

-

Single Molecule Spectroscopy

-

Particle Tracking

-

Light-sheet Microscopy

-

Nanoscopy

-

Atomic Force Microscopy

Since its founding, Piezoconcept has developed a range of ultra-stable nanopositioners able to meet a wide range of microscopy applications with significant advantages over the currently available nanopositioners. The sensors used outperform high-end capacitive sensor because of their exceptionally high signal, leading to picometric stability. Also, because of the very low-noise electronics and the flexure design stage Piezoconcept offers, they can ensure subnanometric (or sub-nanoradian) noise floor.

Featured Products

FOCS.100

The FOCHS.100 is a tubular design piezostage dedicated to microscope objective high speed nanopositioning. The product is offered with 100 microns of travel. The FOCHS.100 is used in a wide range of applications including Z-stack, laser machining and autofocusing. It can work also together with other Piezoconcept automated focus stabilization devices. The stage is made from aluminium, steel and brass and is equipped with sensor offering stability in the picometer level.

The brass mounting ring can be easily exchanged so that almost any objectives can be used with the FOCHS.100 nanopositioner. The threads which are available are : RMS, M25, M26, M27 and M32.

Specifications:

Unit

FOCHS.100

Range of motion

Resolution

Typical noise floor

Full range repeatability

Linearization (typical)

Resonant frequency

Stiffness

Maximum load* :

– horizontal use

– vertical use

Sensor

Size Diameter x H

Material

Cable length

Controller

(µm)

(nm)

(nm)

(nm)

(Hz)

(N/µm)

(kg)

(kg)

(mm)

(m)

100

0,1

0,01

0,2

0,02%

1 175

3,5

0,5

0,5

Silicon HR sensor

Ø 65,5 x 50,3

Al

2

High Speed

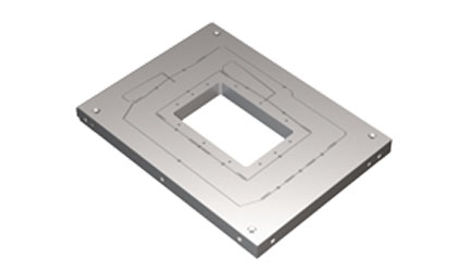

Z-INSERT

The Z-INSERT fits directly any standard 160mm x 110mm opening (K-type frame) which is used on most motorized stages provided by other manufacturers. It provides a 128.5mm by 86.5mm opening that accepts directly any multi-well microplates with an SBS Standard 127.5 x 85 mm (5″ x 3 1/3”) footprint, for example, the 96-well microplate.

The Z-INSERT is compatible with the following stages:

-

ASI – MS-2000 Flat Top XY/XYZ motorized stage (a special version is needed for non-flat top stage)

-

Leica – Regular 3-plate stage

-

Ludl – BioPrecison2

-

Marzhauzer – Scanning Stage SCAN IM 120×80

-

Nikon – Ti XY motorized stage

-

Olympus – IX3-SSU

-

Prior – K type Frame

-

Zeiss – K type Frame

The Z-INSERT is also compatible with most top-mounted incubation chambers.

Specifications

100

0,1

0,01

0,2

0,02%

500

0,6

1

0,5

Silicon HR sensor

148 x 220,5 x 27,3

Al

2

Standard

(µm)

(nm)

(nm)

(nm)

(Hz)

(N/µm)

(kg)

(kg)

(mm)

(m)

Range of motion

Resolution

Typical noise floor

Full range repeatability

Linearization (typical)

Resonant frequency

Stiffness

Maximum load* :

– horizontal use

– vertical use

Sensor

Size W x L x H

Material

Cable length

Controller

Unit

Z-INSERT.100

Z-INSERT.200

Z-INSERT.300

Z-INSERT.500

200

0,2

0,02

0,4

0,02%

400

0,5

1

0,5

Silicon HR sensor

148 x 220,5 x 27,3

Al

2

Standard

300

0,3

0,03

0,6

0,02%

350

0,4

1

0,5

Silicon HR sensor

148 x 220,5 x 27,3

Al

2

Standard

500

0,5

0,05

1,0

0,02%

250

0,25

1

0,5

Silicon HR sensor

148 x 220,5 x 27,3

Al

2

Standard

LT2

The LT2 is a 2-axis stage (X, Y) with a travel range of 100μm, 200µm or 300µm for each axis. Because of its very low profile (15,5mm), this nanopositioner is easy to integrate into inverted microscopes and can be proposed with a coarse positioning stage.

As standard, the LT 2 is made in aluminum but for Bruker AFM upgrade, Piezoconcept can propose the LT 2.100 (100µm version) in Invar which leads to higher thermal stability.

Specifications

300

0,3

0,03

0,6

0,02%

300/250

0,4/0,3

1

0,5

Silicon HR sensor

155.5 x 152.5 x 15.5

Al

2

Standard

200

0,2

0,02

0,4

0,02%

400/350

0,5/0,4

1

0,5

Silicon HR sensor

155.5 x 152.5 x 15.5

Al

2

Standard

Unit

LT2.100

LT2.200

LT2.300

Range of motion

Resolution

Typical noise floor

Full range repeatability

Linearization (typical)

Resonant frequency

Stiffness

Maximum load* :

– horizontal use

– vertical use

Sensor

Size W x L x H

Material

Cable length

Controller

(µm)

(nm)

(nm)

(nm)

(Hz)

(N/µm)

(kg)

(kg)

(mm)

(m)

100

0,1

0,01

0,2

0,02%

500/400

0,6/0,5

1

0,5

Silicon HR sensor

155.5 x 152.5 x 15.5

Al or Invar

2

Standard

BIO2

The BIO2 is a 2 axis ultra-low profile nanopositioner designed to be integrated in any kind of inverted microscopes. Microscope slides can be accommodated inside its rectangular aperture. Because of its very low profile (15,5mm), this nanopositioner is easy to integrate into inverted microscope and can be proposed with a coarse positioning stage.

As standard, the BIO2 is made in aluminum but for Bruker AFM upgrade, we can propose the BIO2.100 (100µm version) in Invar, which leads to higher thermal stability.

100

0,1

0,01

0,2

0,02%

500/400

0,6/0,5

1

0,5

Silicon HR sensor

206.5 x 152.5 x 15.6

Al or Invar

2

Standard

(µm)

(nm)

(nm)

(nm)

(Hz)

(N/µm)

(kg)

(kg)

(mm)

(m)

Range of motion

Resolution

Typical noise floor

Full range repeatability

Linearization (typical)

Resonant frequency

Stiffness

Maximum load* :

– horizontal use

– vertical use

Sensor

Size W x L x H

Material

Cable length

Controller

200

0,2

0,02

0,4

0,02%

400/350

0,5/0,4

1

0,5

Silicon HR sensor

206.5 x 152.5 x 15.6

Al

2

Standard

300

0,3

0,03

0,6

0,02%

300/250

0,4/0,3

1

0,5

Silicon HR sensor

206.5 x 152.5 x 15.6

Al

2

Standard

Unit

BIO2.100

BIO2.200

BIO2.300

TT2

The TT2 is a 2-axis stage (Theta, Phi) with a range of motion of either 5 mrad or 10 mrad (for each axis). The TT2 is the ideal tool for applications where an optical beam steering is necessary. This makes this high-speed stage a best-seller for applications such as particle tracking, optical tweezer, beam stabilization, and scanning microscopy.

This nanopositioner is part of our high-speed product line (High power controller available). When used with the high-power controller, high speed scan at 500Hz and step response time smaller than 2ms are possible.

Unit

TT2.5

TT2.10

10

0,01

0,001

0,02

0,02%

2200/1200

N/A

0,2

0,2

Silicon HR sensor

51 x 64,35 x 43,2

Al

2

Standard or High Speed

Range of motion

Resolution

Typical noise floor

Full range repeatability

Linearization (typical)

Resonant frequency

Stiffness

Maximum load* :

– horizontal use

– vertical use

Sensor

Size W x L x H

Material

Cable length

Controller

(mrad)

(µrad)

(µrad)

(µrad)

(Hz)

(N/µm)

(kg)

(kg)

(mm)

(m)

5

0,005

0,0005

0,01

0,02%

4000/2000

N/A

0,2

0,2

Silicon HR sensor

51 x 64,35 x 43,2

Al

2

Standard or High Speed

C3.100

The C3.100 has been specifically designed for offering 100µm travel range in a compact design. This stage is also available in 2 axis version (C2.100) but also in 1-axis version either with X axis (CX.100) or Z axis (CZ.100).

This stage has received an overwhelming success for fiber alignment and laser writing application.

100

0,1

0,01

0,2

0,02%

400/250/220

0,3/0,3/0,6

0,5

0,1

Silicon HR sensor

48,5 x 48,5 x 48,7

Al – SS

2

Standard

(µm)

(nm)

(nm)

(nm)

(Hz)

(N/µm)

(kg)

(kg)

(mm)

(m)

Range of motion

Resolution

Typical noise floor

Full range repeatability

Linearization (typical)

Resonant frequency

Stiffness

Maximum load* :

– horizontal use

– vertical use

Sensor

Size Diameter x H

Material

Cable length

Controller

Unit

C3.100

Please contact us for additional detail on these products and others